wear ring centrifugal pump|centrifugal pump clearance : warehouse Wear rings play a crucial role in centrifugal pumps. A centrifugal pump typically features two adjacent wear rings: a stationary wear ring on the casing and a rotating wear . webHonors & Awards. When you choose to play with 888, your are basically choosing to enjoy playing with a top-notch high experience brand. 888 has been awarded numerous accolades by world’s leading authorities in .

{plog:ftitle_list}

Get up to 3 months free of Apple Music. Listen to Barulho Do Foguete (Ao Vivo) by Zé Neto & Cristiano. See lyrics and music videos, find Zé Neto & Cristiano tour dates, buy .

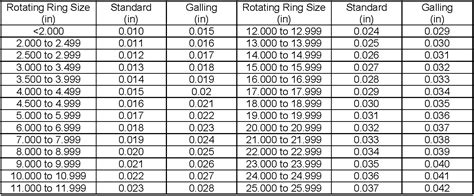

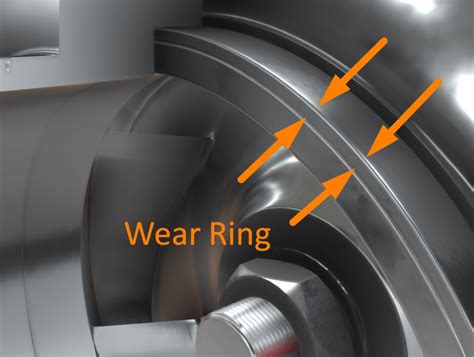

Wear rings play a crucial role in centrifugal pumps. A centrifugal pump typically features two adjacent wear rings: a stationary wear ring on the casing and a rotating wear . Wear Rings 101: Basics, Location, Fit, Clearances & Material Selection. All centrifugal pumps contain rotating impellers within stationary casings. As a pump impeller .What is the use of Wear rings in centrifugal pumps? Wear rings, also known as wearing rings or impeller wear rings, are important components used in centrifugal pumps to reduce fluid leakage and improve pump performance. . What’s the minimum clearance for a pump wear ring? Compliance with the standards for API 610 wear ring clearances ensures that wear rings are unlikely to come in contact with one another. The specified minimum clearances get larger as the rings get larger: For a wear ring with 2” diameter or less, API lists the minimum diametral clearance .

Cornell Pump produces how-to videos, explaining successful ways to operate and maintain pumps. We recently added a short video on how to install and remove a wear ring. Many of our pumps employ wear rings, and this method can safely and effectively help you .

As operating plants age, so does their equipment. Pumps will need to be replaced or repaired, and in many cases, upgraded. A non-metallic wear ring is an option that may make the pump more reliable and increase its .Gene Vogel EASA Pump & Vibration Specialist One of the most common repairs on centrifugal pumps is replacing worn or damaged wear rings. For pumps with closed style impellers (impellers with a front shroud as described below), there will be a casing wear ring and possibly an impeller wear ring which is fitted to the outside diameter (OD) of the impeller suction eye. .

One of the most common repairs on centrifugal pumps is replacing worn or damaged wear . Pumps & Systems June 2019: Wear Ring Clearance For Centrifugal Pumps Understand the pump specific speed to help establish proper tolerance. So a wear ring not just protect from any possible damage but also helps improve pump efficiency. Effects Of Increase In Wear Ring Clearance On Centrifugal Pumps. A wear ring affects the working and performance of an centrifugal pump in a significant way. Centrifugal pumps with high wear ring clearance show an increase in its thrust and vibration. It is also worth considering the effect of wear ring clearances on pump vibration. With a reduction in clearance, the effective shaft stiffness will increase. . Reference: API Standard for Centrifugal Pumps, 11 th Edition. Most popular related searches. centrifugal pump; centrifugal pumping; impeller pump; wear metal; reference standard .Both impeller and case wear rings are commonly found in centrifugal pumps. These pumps are used in many applications to transfer energy by centrifugal force. As the impeller of the centrifugal pump rotates, the fluid is pushed outward along the circumference and directs the flow towards the pump outlet as depicted in Figure 1.

impeller wear ring clearance table

A centrifugal pump wear ring is a close clearance device present in most (but not all) centrifugal pumps. The vast majority of them are radial clearance devices (we'll talk about other variants in .Gene Vogel EASA Pump & Vibration Specialist One of the most common repairs on centrifugal pumps is replacing worn or damaged wear rings. For pumps with closed style impellers (impellers with a front shroud as described below), there will be a casing wear ring and possibly an impeller wear ring which is fitted to the outside diameter (OD) of the impeller suction eye. . Centrifugal Pump Wear Ring. Those of us who deal with the specification, design, manufacture and troubleshooting of these machines on a daily basis often forget that this simple part belies a lot .

Part Two examines the impact of pump wear ring clearance on pump efficiency.For decades, pump designers have known that increasing wear ring clearance leads to a loss of efficiency. However, with metal wear rings, even the minimum clearance as specified by API610 is substantial.Learn about nine different centrifugal pump parts that you may find in almost all pumps.Body, Casing, Impeller, Wear Ring, Shaft, coupling, Bearing and Beari.The centrifugal pump’s impeller rotates, pushing the fluid outward along the circumference and directs the flow towards the pump outlet as depicted in Figure 1. . Custom Wear Ring Grades. While carbon/graphite is a beneficial fail-safe, it is also beneficial when the pump is operating successfully. Carbon/graphite can be impregnated with .Centrifugal Pump Wear Ring: Enhance Efficiency & Longevity. Centrifugal pumps are widely used in various industries to move liquids efficiently. A critical component that plays a significant role in maintaining the efficiency and .

Gene Vogel EASA Pump & Vibration Specialist One of the most common repairs on centrifugal pumps is replacing worn or damaged wear rings. To restore efficient, reliable operation and prevent catastrophic pump failure, it is critical to restore proper clearances between the stationary casing wear ring and the rotating impeller wear ring. Although many pump manufacturers .

In centrifugal pumps, wear materials are used as a buffer between rotating and stationary parts. Historically, these components have been metallic in nature. To avoid galling and possible equipment seizure, dynamic metal clearances . casing and impeller for the composite wear ring and pump hardware (casing ID and impeller shaft OD).

ring openings can result in a high wear rate. . Erosion wear of the centrifugal pump components is considered one of the principal hurdles for pumping and transporting the particle-fluid flow in . Figure 1 plots the clearances specified for wear rings in API 610 (1) and in the Pump Handbook (2) as a function of the ring diameter. To obtain optimum (hydraulic and mechanical) performance, manufacturers want to provide centrifugal pumps with minimum clearance between wear rings.

torsion test in the plastic range

normal pump model and WPM represents the wear-ring abrasion pump model. In the test, energy performance and vibration test are conducted for the normal pump and the wear-ring abrasion pump respectively. For WPM, only the clear-ance of the front wear-ring is changed from 0.15mm to 0.75mm. The specific scheme of the test is shown in Table 1. These blades are fixed to the diffuser ring. The space between the blades defines the direction of the liquid flow. Fluid from the impeller flows through the cavities under high pressure. Upon exiting the blade, the liquid enters the housing of a volute or spherical shape. . Centrifugal pump has less wear and tear and can handle dirty water.Gene Vogel EASA Pump & Vibration Specialist One of the most common repairs on centrifugal pumps is replacing worn or damaged wear rings. For pumps with closed style impellers (impellers with a front shroud as described below), there will be a casing wear ring and possibly an impeller wear ring which is fitted to the outside diameter (OD) of the impeller suction eye. .

torsion test instron

The clearance of wear-rings in the impeller of centrifugal pumps has an important influence on the pump's performance. Unfortunately, this effect has not been quite well documented, especially for .Reducing the wear ring clearance in a centrifugal pump is a signifi- cant reliability upgrade because it increases rotor damping and stiffness in the pump. In more practical terms, reducing wear ring clearance decreases vibration and shaft deflection. The relationship between shaft deflection and reliability is clearly known. The video we are featuring today, shows how to easily and efficiently install and replace wear rings on a centrifugal pump backplate. Watch this procedure, and learn more about pump repair and maintenance on our YouTube Channel. You can also suggest new video topics at [email protected]. Previous.

In order to explore the influence of different wear-ring sizes on the performance and flow characteristic, both numerical simulation and performance test are conducted in a centrifugal model pump . As centrifugal pumps must transport liquids by imparting kinetic energy to the fluid, the impeller of a centrifugal pump must rotate at a fast velocity to do this. Due to shaft deflection, these high speeds may cause excessive wear on the impeller and casing, leading to premature failure. How Wear Rings Help to Improve Pump Performance. With .

impeller wear ring and casing

centrifugal pump wear ring function

12 de mar. de 2023 · A maior fábrica de monstros do mundo conta com James Sullivan, um dos monstros mais assustadores, que tem o pelo azul e chifres, além de seu assistente e melhor amigo Mike, um monstro verde de.

wear ring centrifugal pump|centrifugal pump clearance